Fuel pellet machine can make pellets from many kinds of biomass raw materials, such as wood, sawdust, bagasse, palm fiber, EFB, coconut shell, hops, straw, stalk, grass, bamboo powder, and so on.

Fuel pellet mill machine classifications

There are mainly 2 types of fuel pellet mills, flat die pellet mill and ring die pellet mill.

Flat die fuel pellet machine:

Flat die pellet machine has a flat die plate, and the biomass is extruded by the roller through the flat die plate holes and pellets go out underneath the flat die and cut by the pellet cutter. Its capacity is 50-800kg/h.There are 2 types of flat die fuel pellet machines: D-type and R-type. D-type is suitable for softwood or crop waste, while R-type is suitable for hardwood. (Want to know more about flat die fuel pellet machines? Click here!)

|

|

| Flat die pellet machine | Ring die pellet machine |

Ring die fuel pellet machine:

Ring die pellet machine has a round die, which looks like a ring. Its capacity can range from 500-2000kg/h. For larger capacity, several sets of ring die fuel pellet machines can be paralleled.Ring die fuel pellet machine is widely used for industrial pellet production. it can be used by woodworking plants like furniture factory, or sugar plants who have large quantity of bagasee, and also palm oil plant who have palm fiber.

Fuel pellet machine details

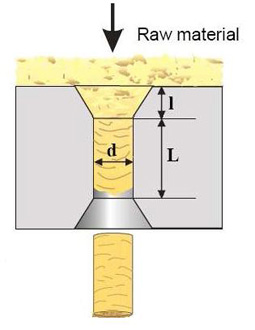

Pellet machine die hole depth:

Pellet machine die hole depth:The pellet machine die hole depth can be represented by “L” in the picture. It plays an important role in pellets furl production. The deeper die hole is, the longer time biomass raw material is heated and pressed, and the better lignin inside the biomass is softened, the harder and denser pellets can be.

Fuel Pellet machine die hole gradient:

The die hole gradient is represented by “l” in the picture. The gradient determines the degree pellets can be pressed. For different raw materials, the gradients are different.

Pellet machine die hole width:

The die hole width (also the diameter), represented by "d" in the picture, can range from 2~8mm. generally, for making fuel pellets used in stove, 6mm die hole is common, while 8mm die hole is usually used to produce pellets fuel for boiler. The larger die hole width is, the less friction there is, and the less obstruction there is. This can improve productivity, but have negative effects on pellets quality.

Materials to produce fuel pellet machine die

There are several kinds of metal to make pellet machine die, and every type has its own advantages and disadvantages. The die plate must have high hardness and be resistant to weariness and corrosion, in order to withstand the force generated in pellets production and improve productivity. Here are some types of metal frequently used to produce pellet machine die.

- Carbon steel alloy

-

Stainless steel

Stainless steel

- High chromium alloy

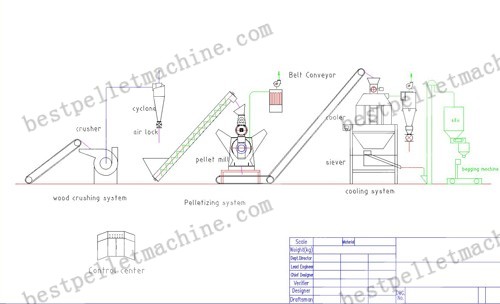

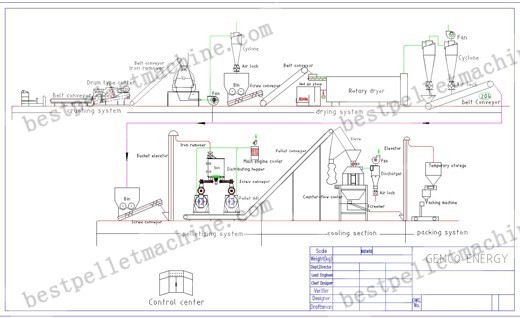

GEMCO fuel pellet machine

Over years of R&D, GEMCO has found the best materials for producing highly efficient fuel pellet machines. GEMCO also has a special raw material testing team to do biomass pellets production test every day, and has gained the most suitable die specifications for most biomasses. GEMCO has built many successful fuel pellet production lines abroad.GEMCO sincerely looks forward to hearing from you!

Previous:wood pellet plant project report

Next:pellet machine china

Quick Message